generally conforms to, CENELEC HD 22.1.S2, DIN VDE 0282 part 810, IEC 245, CEI 20-19 & BS 6007, BS 6899

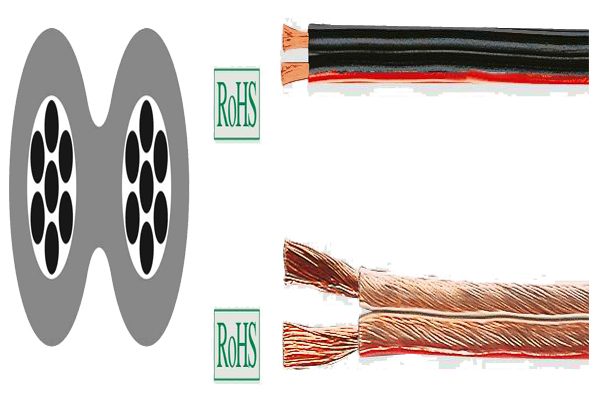

Copper:

EC flexible copper generally conforms to IEC 60228, DIN VDE 0295,IS 8131

Insulation:

Special Rubber EPR, EPDM core

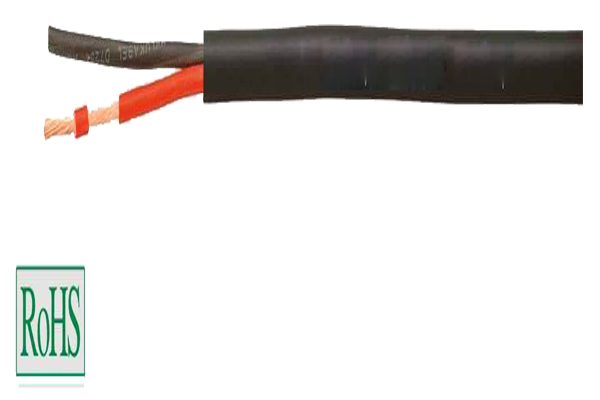

Outer Sheath:

Special Rubber : Black, Blue

*Any other Color on specific request can also be supplied